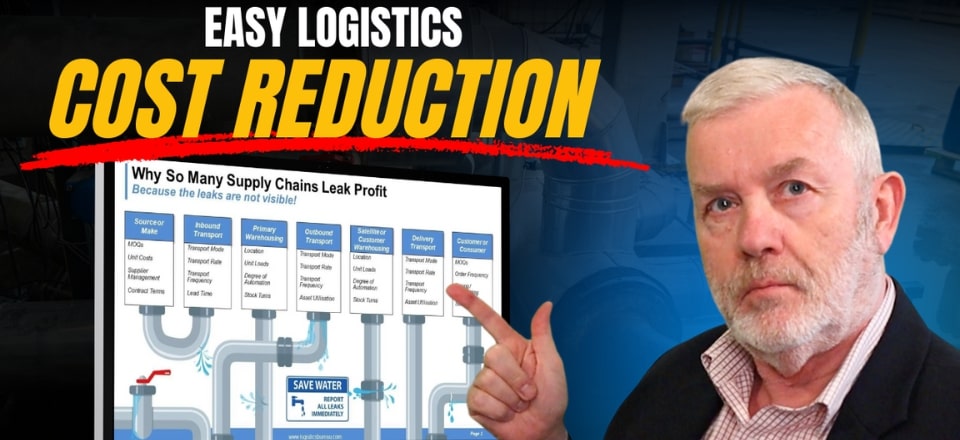

The main reason businesses often overlook these issues is that fixing them feels too complicated. Addressing loss-making products and customers requires a cross-functional approach, which means it’s not just about improving one area of the business. It’s a holistic problem that spans procurement, inventory management, customer service, and forecasting. Take low-margin products, for example. Companies often resist eliminating unprofitable products because they’re concerned about disrupting their product range or losing sales…